What is 3D printing?

3D (three-dimensional) printing refers to the process of additive manufacturing (AM) that crafts and produces the physical manifestation of any digital design. In theory, it’s similar to conventional 2D printing technologies, but instead of a flat output, the printing process is repeated over and over as layers. Imagine a glue gun attached to a mechanical robot arm that lays down consecutive thin layers of material referred to as filament. Depending on the application, the materials and methods can differ.

Basically, a 3D print is the assemblage of multiple thin layers of the design’s cross-sections through additive manufacturing. And unlike subtractive manufacturing, which involves the removal of a material’s body such as milling, 3D printing enables you to create complicated designs without any material wastage.

How does 3D printing work?

3D printing works through a variety of methods, but at its core, it all begins with a computerized design or a 3D model, which you can craft yourself or download from 3D model designers or printers. Through a 3D printer, this computerized design can come to life through the additive manufacturing of its physical form. As mentioned earlier, 3D printing makes use of conventional 2D printing methodologies, but it layers the material and produces a three-dimensional “print out.”

So, basically, if you want to get into 3D printing, here are the essential elements to get started:

- 3D modeling and slicing software

- 3D printing materials (also referred to as filament)

- 3D printing equipment or tools

And here are the most common methods of 3D printing:

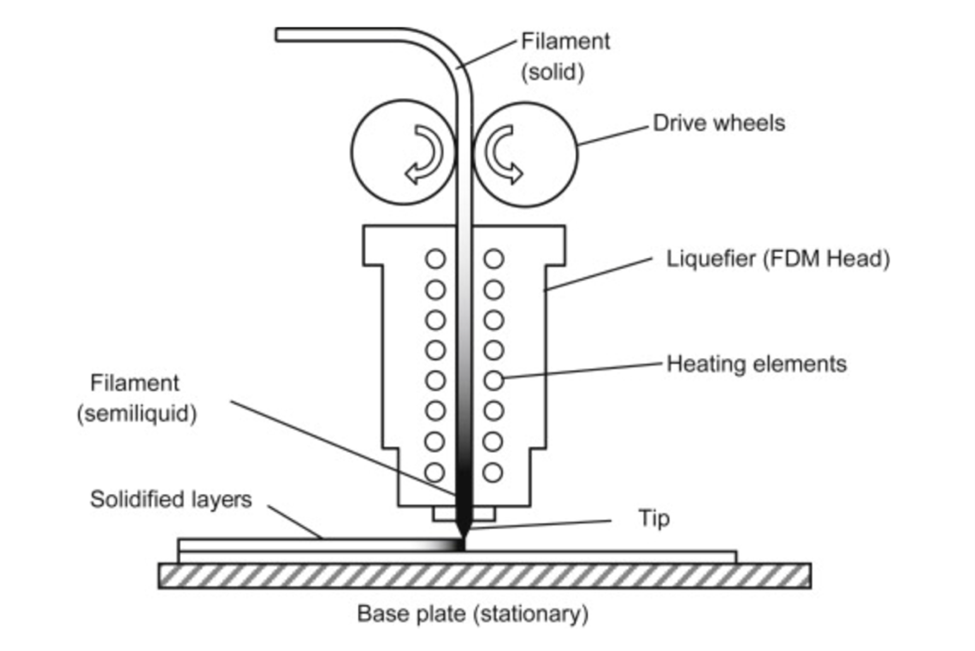

- Fusion Deposition Modeling (FDM) is the most widely used method for consumers, which refers to the 3D printing process that makes use of a machine that melts the material and pushes it out through a nozzle, creating layers of the 3D model.

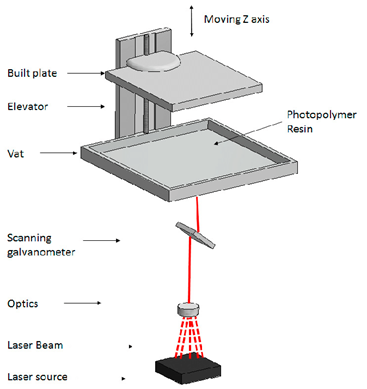

- Stereolithography (SLA) refers to vat photopolymerization, or simply put, resin 3D printing, which is the process that uses UV lights on photoreactive resins that solidify and form the 3D model upon exposure. This allows for the crafting of finer details when compared to FDM.

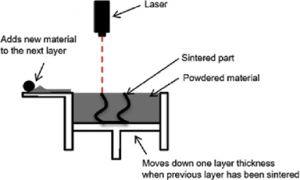

- Selective Laser Sintering (SLS) refers to the 3D printing process that involves the sintering (or the heating of a powdered substance into coalescence) of a bed of finely powdered material. The machine then sweeps or pushes more powder onto the sintered layer until the object is produced. SLS 3D printing isn’t a common sight on the consumer level, and is more prevalent in large scale industrial manufacturing applications, such as the parts of a space rocket.

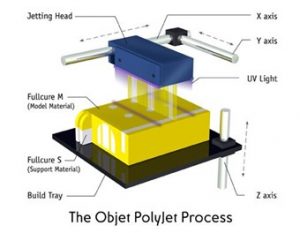

- PolyJet is a 3D printing technique that combines the critical processes involved in FDM and SLA, wherein the machine squirts successive droplets of photoreactive resin onto a build surface and are then immediately exposed to UV light, hardening the material into the form. This allows for the production of objects with high precision and detailed accuracy.

How does a 3D printer work?

Now that you know the four of the widely used 3D printing techniques, let’s discuss how a 3D printer works. But first, you must be thinking, what is a 3D printer?

At its core, a 3D printer is a piece of equipment that utilizes CAD (computer aided design) to produce a physical object of a 3D model from a range of materials, which are referred to as filament. These can be any of the following: plastics, powders, resins, metals, wood, and carbon fiber, among others.

Depending on the 3D printing technique you’re using, a 3D printer will involve different processes, but will generally include heating and cooling filament. However, the most accessible 3D printers often use FDM, which works like a glue gun and inkjet printer combined. That being said, 3D printing usually works from the ground up, which means it starts at the bottom or base of an object and moves upwards through the layering process.

How does 3D printing work?

There are a variety of 3D printing software available relative to your needs. And whether you’re a hobbyist or manufacturing professional, choosing the right tools can help make your job easier.

Adamenfroy.com lists down 17 of the best 3D printing software tools out in the market, but here are three to get you started:

- Autodesk Fusion 360 tops the list as the preferred 3D printing software for mechanical engineers, designers, and machinists, because it seamlessly integrates and streamlines product development through the combination of design, engineering, and manufacturing.

It is best for the manufacture of mechanical parts. Its key features as a platform includes full control over design modeling, real-time collaboration, and design simulation. - Autodesk AutoCAD comes in second and is the most suitable for 3D printing professionals. It is versatile and comes with a handful of capabilities and features, such as excellent data presentation and analytics.

It is recommended for experienced users who are looking for a high-end suite of 3D printing tools. Its key features include efficient and powerful capabilities that cover detailed 3D modeling, online and smartphone use, file conversion and formatting compatibilities, and a wide range of software plugins. - TinkerCAD is a free online 3D modeling tool that simplifies the 3D printing process without compromising the capacity to design complicated shapes and objects.It is recommended for beginners and professionals that offers key features like: STL (Standard Tessellation Language) file support, laser cutting capability, cloud storage, and an easy-to-use UI. However, it does have some cons, such as the designed object having certain limitations.

If you’re a total beginner and are looking for a 3D printing software that specifically caters to newbies, here are 3 of the 11 best 3D modeling software tools for beginners as listed by 3D Natives:

- Leopoly is a cloud-based 3D modeling software recommended for new 3D modelers and designers like students and consumers for its simplicity and straightforward usability as a platform. With Leopoly, you have access to easy customization options when modeling an object, which you can import from a library of readily available objects or gallery by other users.

- Morphi is a 3D software app for tablets, which makes it easily accessible to many 3D printing It enables you to design 3D models through a simple interface that offers an extensive library of ready-made models you can modify and transform. It is free to use, which is another reason it’s perfect for beginners, although there are features that you can access through paid subscriptions.

- BlocksCAD is a 3D software specifically built for educational purposes, which makes it fairly straightforward to use for beginners in 3D modeling. Its UI/UX utilizes colored blocks that denote shapes and transformations. BlocksCAD is compatible with its professional version, OpenSCAD, which allows you to make more refined edits to the 3D model you designed prior to printing.

And just like printing your files through any typical printer, your 3D design should be saved in a file format that is compatible with the software and hardware. In this case, 3D printing will often require a .STL or .OBJ format.

What is “slicing” in 3D printing?

Once you have a printable file of your 3D model, such as the stereolithography or .STL file format, your slicing program serves to convert this file into a form, such as G-code, that the 3D printer can understand. As mentioned earlier, 3D printing involves the successive layering of filament, and slicing makes this process possible. So, why is slicing necessary?

3D printing technology, at its currently level of sophistication, is limited by its capability to understand three-dimensional concepts as a form. This limitation is overcome by slicing. A slicing software utilizes the scans of a 3D model and recreates every layer into hundreds and thousands of thin cross-sections. This also includes how and where the object is filled solid, with lattices, or beams and columns for foundational support.

Once the 3D model has been sliced, it’s now ready for the actual 3D printing process. You can input the file into the 3D printer through a USB port, SD card reader, or Wi-Fi.

Here are some slicing programs to choose from:

- Z Suite

- AstroPrint

- Simplify3D

- CraftWare

- Cura

What is a good 3D printer?

- The Anycubic Vyper, as an entry-level 3D printer, offers affordability, convenient installation, and ease of use. Priced at 359 USD, the Vyper’s key features include: auto leveling, fast assembly through its integrated build, a large-size touch screen for accessible and easy UI, and stepper drivers that keep your printer quiet as it operates.

- The Flashforge Inventor II is designed for educational use, which makes it easy to operate. As a mid-level 3D printer, it comes at a price tag of 629 USD. With key features such as: a build volume of nearly 6” all around with up to 400-micron layer resolution and a single extruder nozzle that uses a 1.75mm filament, the Flashforge Inventor II is your buddy for hobbyist-level 3D printing

- The BCN3D Sigma D25 offers you the productivity, power, and precision you’re looking for in a high-end 3D printer, as it’s the compact version of its industrial large-format 3D printer predecessor. This model is a dual extruder printer, which allows you to print dual-color objects at the same time, and it also provides a larger build space than the other printers in this list. At 3,995 USD, the Sigma D25 can truly help you create 3D-printed prototypes better than ever.

What can you make with a 3D printer?

3D printers can produce tiny objects, like jewelry, trinkets, and toys; massive things you wouldn’t have thought possible, such as rocket parts, ships, and houses; and even life-changing items, like food, prosthetic body parts, and human organs for transplant.

Here are some of the useful and cool projects you can try out with a 3D printer at home:

- Plastic, wood, or metal stands for your smartphone, tablet, or laptop

- A detachable amplifier for your speakers

- A handheld notebook case for your smartphone

- Charger cable savers

- Cases and holders for your wired earphones and headphones

- USB cable organizer

- Cable spools

- Blade-key

- Carabiner

- Reusable bag clips

- Juicers

- Bottle openers

- Toothpaste tube squeezer

- Wall-mounting soap dish

- A mini combination safe

- Self-watering planter (pot and reservoir)

- Whistle

- Ball-jointed toys and articulated figures

- Face shields

- Dining utensils like spoons, forks, and kitchen knives

3D printing can be used in different industries, from automotive and aviation, to construction, consumer products like shoes and sunglasses, healthcare, dental, food manufacturing, and education sectors – among many others.

What materials can be 3D printed?

- Plastic (PLA, ABS, PVA, PC)

- Powder (Polyamide, Alumide)

- Resin (High-detail, paintable, or transparent types)

- Metal (Stainless steel, bronze, gold, nickel, aluminum, titanium)

- Carbon Fiber

- Graphite and Graphene

- Nitinol

- Paper

- Other composites like food and biomaterials